Cova-Wall® Direct Fix System has two Panel options:

OPTION 1: Plain EPS Panel Types:

1a. Plain EPS Panel

1b. Vented EPS Panel (Panel with vented strips (grooves); strips mounted vertically when fixed to wall frame and facing wall wrap, allows cavity to breath better in humid and wet conditions than Plain Panels).

OPTION 2: Pre-Rendered EPS Panel:

Pre-Rendered Panels are factory coated with polymer-modified render and alkaline-resistant fibreglass mesh, ready to be anchored to frame and thereafter coated with only mesh on joints and not entire Panel).

Plain EPS Panel System specifications

Important features

It consists of Plain and Vented EPS Panels as stated above.

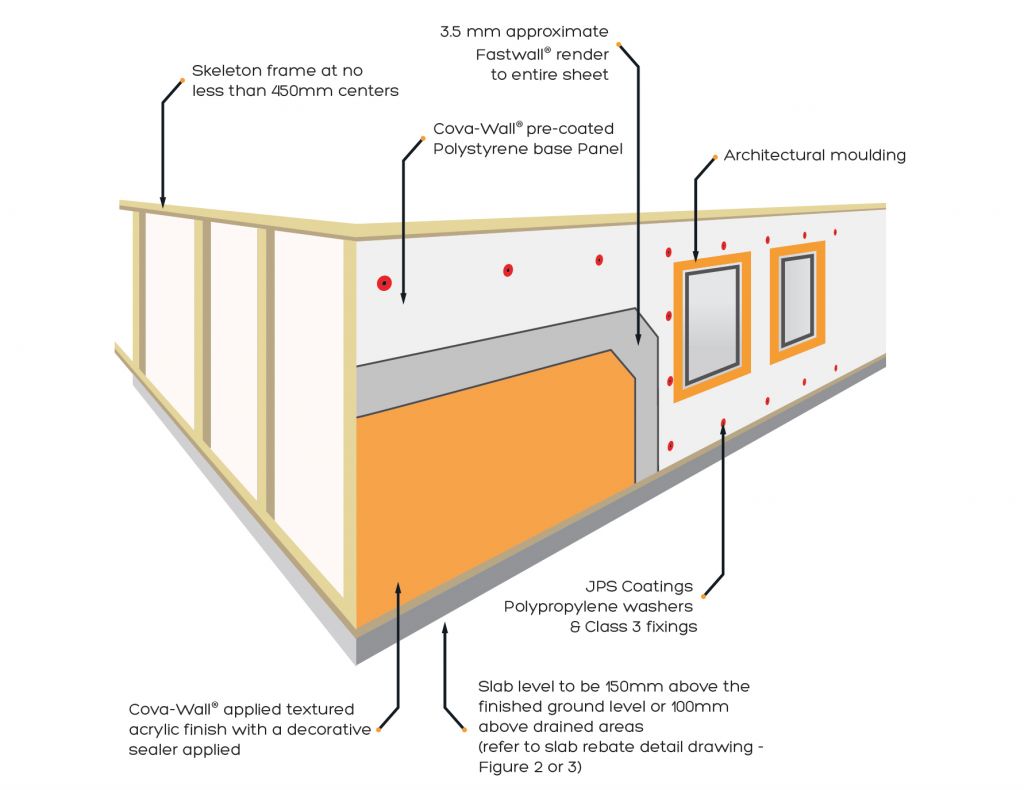

General Description

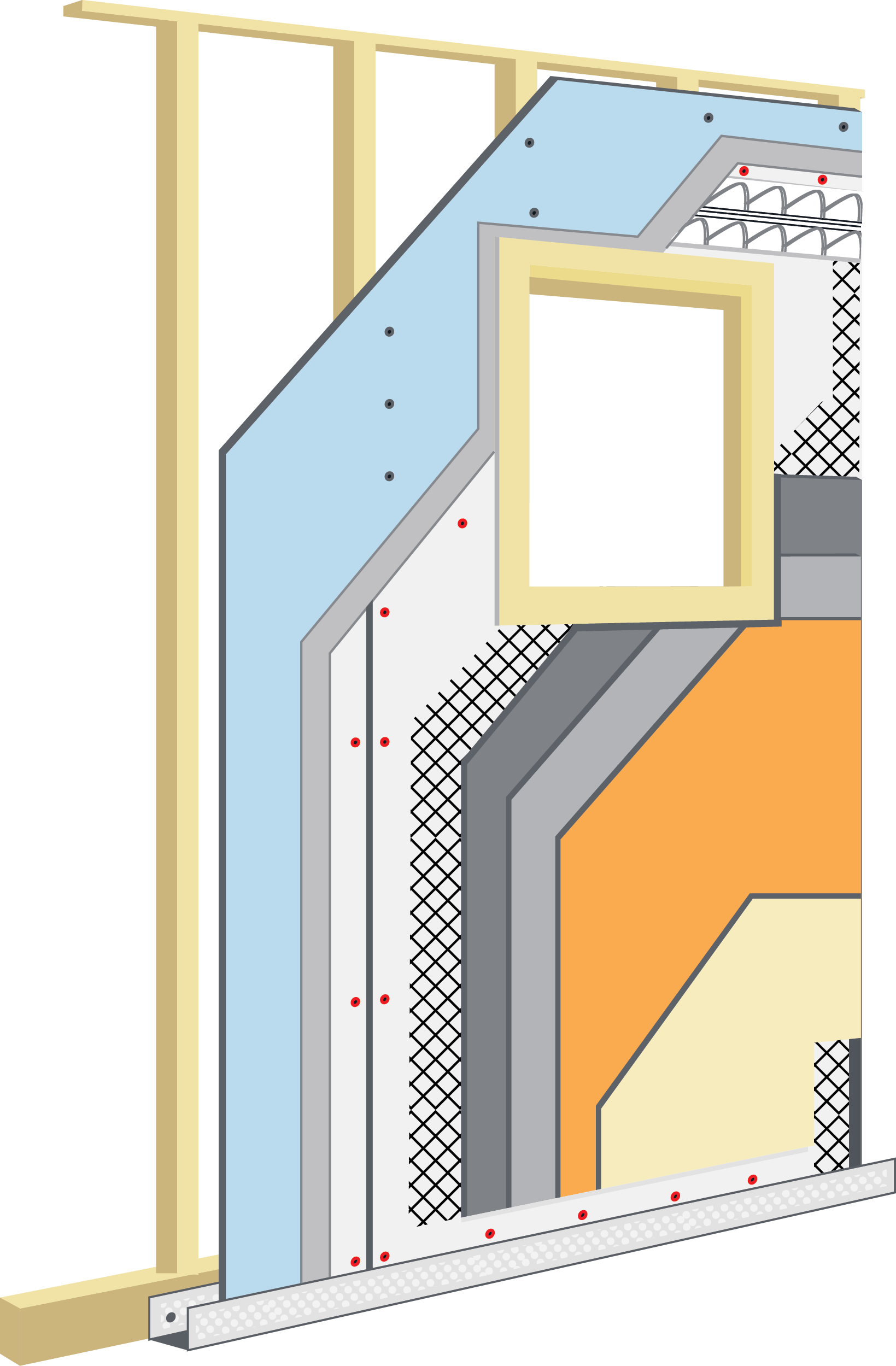

Plain EPS Panels are used in this system. Panels are fastened and fixed directly on to timber or steel framed buildings having a Weatherproof Breathable Wall Wrap (Sarking) in between. A Starter Channel Bead is fixed on to the bottom frame in required size. The Panels are installed horizontally, and fastened directly onto the studs using screws and plastic washers. The Panel joints are then sealed with PU Foam Adhesive. Corner angle beads are fixed and a coat of Patch `Em-Up® is applied. Fibreglass mesh is stuck across the entire Panel surface and The Panels are coated with more Patch `Em-Up® to a thickness not less than 2mm. The Panel is then coated with Fastwall Render® to a thickness between 2-4mm and finished as per the Cova-Wall® coating system consisting of two coats of polymeric render (base coat) and one coat of acrylic texture, followed by a coat of Decorative top coat sealer having a total minimum coating thickness of 5-6mm.

Pre-Rendered EPS Panel System specifications:

Important features

It consists of Pre-Rendered EPS Panels as stated above.

General Description

Plain EPS Panels are used in this system. Panels are fastened and fixed directly on to timber or steel framed buildings having a Weatherproof Breathable Wall Wrap (Sarking) in between. A Starter Channel Bead is fixed on to the bottom frame in required size. The Panels are installed horizontally, and fastened directly onto the studs using screws and plastic washers. The Panel joints are then sealed with PU Foam Adhesive. Corner angle beads are fixed and a coat of Patch `Em-Up® is applied. Fibreglass mesh is stuck across the entire Panel surface and The Panels are coated with more Patch `Em-Up® to a thickness not less than 2mm. The Panel is then coated with Fastwall® Render to a thickness between 2-4mm and finished as per the Cova-Wall® coating system consisting of two coats of polymeric render (base coat) and one coat of acrylic texture, followed by a coat of Decorative top coat sealer having a total minimum coating thickness of 5-6mm.